Microsoft has announced a new cooling system that can remove heat from AI chips up to three times more effectively thancurrent methods. The company tested the in-chip microfluidic cooling technology on a server running simulated Teams services, showing its potential to support next-generation data centres.

A Microsoft Teams call might look simple, but it actually relies on hundreds of different services working together in the background. One service connects the user to the meeting, another hosts it, while others handle chat storage, merge audio, record conversations or create transcripts.

Each of these tasks puts pressure on different parts of the server. “The more heavily utilised a server is, the more heat it generates, which makes sense,” Jim Kleewein, technical fellow at Microsoft, explained.

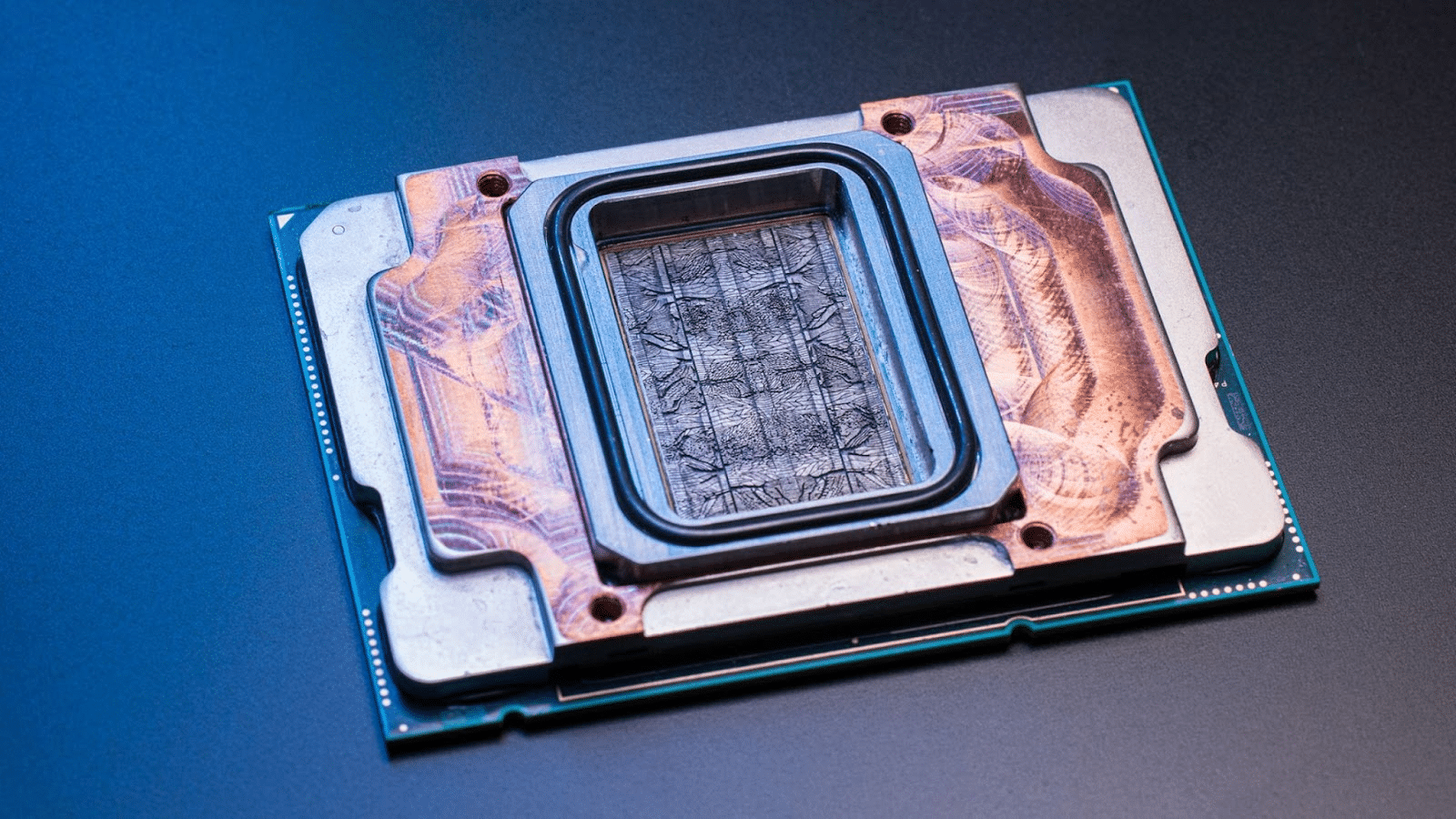

The system utilises microchannels etched directly into the silicon, enabling coolant to flow directly onto the chip, where heat is concentrated.

“If you’re still relying heavily on traditional cold plate technology, you’re stuck,” Sashi Majety, senior technical programme manager at Microsoft, said. The company expects the innovation to help overcome rising heat issues caused by increasingly powerful AI chips, as it expressed in its blog post.

Judy Priest, corporate vice president and chief technical officer at the company, said the breakthrough “would allow for more power-dense designs that will enable more features that customers care about and give better performance in a smaller amount of space.”

To achieve this, the team combined microfluidics with AI to map unique heat signatures and direct coolant precisely. Microsoft also worked with Swiss startup Corintis to design bio-inspired channels that mimic veins in leaves to optimise cooling efficiency.

The giant said the cooling method could improve energy efficiency and lower costs in data centres, where heat management is a growing challenge. “Microfluidics improves cost, reliability, speed, consistency of behaviour and sustainability,” Kleewein said.

The company is now exploring how to integrate the technology into future chip generations and data centre operations. It also plans to continue collaborating with silicon manufacturers to scale the system. “We want microfluidics to become something everybody does, not just something we do,” Kleewein added.